Understanding the Role of Silicone Injection Molding Manufacturers in Electronics and Medical Supplies

In the ever-evolving world of manufacturing, silicone injection molding has emerged as an invaluable process that offers superior quality and flexibility, particularly in two critical sectors: electronics and medical supplies. Companies like Nolato exemplify the expertise and capabilities that silicone injection molding manufacturers bring to the table.

What is Silicone Injection Molding?

Silicone injection molding is a highly efficient manufacturing process that involves injecting silicone rubber material into a mold to create various products. This technique is favored for its precision, ability to produce complex designs, and suitability for high-volume production runs. The properties of silicone, such as its durability, flexibility, and resistance to high temperatures, make it an ideal choice for numerous applications.

Key Advantages of Silicone Injection Molding

- Versatility: Silicone can be molded into various shapes and sizes, allowing for the creation of unique designs tailored to specific requirements.

- Durability: Silicone products exhibit excellent longevity and performance even under demanding conditions.

- Temperature Resistance: Silicone maintains its properties across a wide temperature range, making it suitable for applications involving extreme heat or cold.

- Biocompatibility: Particularly in the medical field, silicone is recognized for its safety and compatibility with human tissue, which is crucial for medical devices.

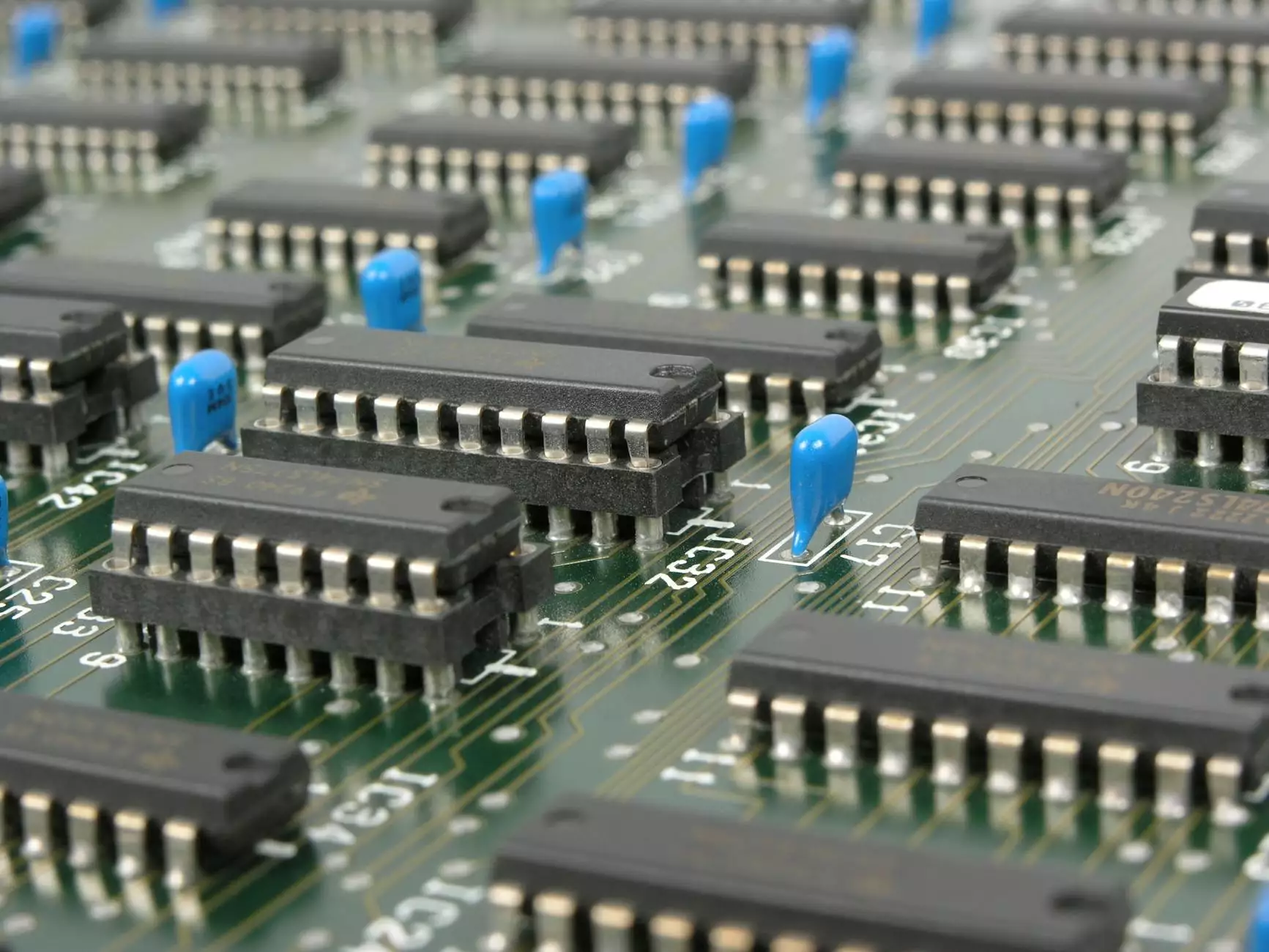

Applications of Silicone Injection Molding in Electronics

The electronics industry heavily relies on silicone injection molding for the production of components that require both performance and longevity. Some notable applications include:

1. Keypads and Buttons

Silicone is commonly used for manufacturing keypads and buttons due to its soft-touch feel and durability. The flexibility of silicone allows for tactile feedback, enhancing user experience.

2. Seals and Gaskets

In electronics, preventing moisture and dust from penetrating devices is crucial. Silicone seals and gaskets offer superior sealing capabilities, protecting sensitive components from environmental damage.

3. Encapsulation

Silicone injection molding is utilized for encapsulating electronic components, providing insulation and protection against shocks, chemicals, and extreme temperatures.

Importance of Silicone Injection Molding in Medical Supplies

In the medical industry, the role of silicone injection molding manufacturers is paramount. The following are significant reasons why silicone is the material of choice:

1. Medical Devices and Instruments

Silicone is extensively used in the production of various medical devices, including syringes, catheters, and implantable devices. Its biocompatibility ensures that these devices can safely interact with human tissue, which is vital for patient safety.

2. Seals for Medical Equipment

Sealing systems crafted from silicone are essential in medical devices that require sterility and safety. These seals help maintain the integrity of sterile environments.

3. Durable and Reusable Products

Many medical supplies are designed for multiple uses. Silicone’s durability makes it an excellent choice for instruments that need to withstand frequent cleaning and sterilization processes.

Why Choose Reliable Silicone Injection Molding Manufacturers?

Quality Assurance

Engaging with reputable silicone injection molding manufacturers such as Nolato assures that the products meet stringent quality standards. High-quality production minimizes defects and enhances the reliability of the end products.

Customization Capabilities

Experienced manufacturers can offer customized solutions tailored to specific applications, ensuring that the products meet both design and functional requirements. This ability to customize can be critical in competitive markets where innovation is key.

Advanced Technology

Leading manufacturers invest in state-of-the-art technology, which not only ensures precision in the manufacturing process but also improves overall efficiency. This commitment to technology enhances their ability to meet current and future market demands.

Looking at the Future of Silicone Injection Molding

As industries continue to advance, the role of silicone injection molding will undoubtedly grow. Innovations in materials and techniques promise to improve the efficiency and effectiveness of this manufacturing process.

1. Sustainable Practices

With an increasing focus on environmental sustainability, many manufacturers are exploring eco-friendly silicone materials and sustainable practices. This shift not only benefits the planet but also appeals to consumers’ growing preference for environmentally responsible products.

2. Increased Automation

The rise of automation in manufacturing is set to enhance production capabilities further. Automated processes can reduce human errors and increase speed, allowing for larger quantities of products to be produced without compromising quality.

3. Innovations in Product Design

As technology evolves, so too do product designs. Manufacturers who adapt to these changes will be able to harness new opportunities, creating innovative products that meet the changing needs of consumers.

Conclusion

In conclusion, the role of silicone injection molding manufacturers within the electronics and medical supplies industries cannot be overstated. Their expertise not only facilitates the production of high-quality silicone products but also propels innovation and sustainability in manufacturing practices. Companies like Nolato continue to lead the way, showcasing the advantages of silicone injection molding in creating durable, versatile, and safe products. As these industries grow and evolve, the importance of high-quality manufacturing processes will remain a critical factor in achieving success and meeting consumer demands.